Pride of Me 私たちが創る未来

広島と共に

成長する

成長する

小川 秀樹

代表取締役社長

参画企業

西川ゴム工業(株)

西川ゴム工業(株)

皆さんは自分の限界を自分で決めていませんか。私たちはこれまで戦争や災害等、苦難な中でも試行錯誤しながら、自分たちの可能性を信じて成長してきました。また、多くの人々の支えやつながりの中でその可能性を広げてきました。どうか皆さんもしなやかでたくましいゴムのような「弾力発想。」で将来を描いてください。そうすることで、素晴らしい未来が拓けてくると私は確信しております。

- 小川 秀樹

広島と共に 西川ゴム工業株式会社

西川ゴム工業の歴史はスポンジ草履から始まり、それ以来スポンジ技術にこだわり続けてきました。

原爆で工場を失い多くの従業員が被災しましたが、生き残った従業員と共に再度ゴム事業を立ち上げていくことを決意し、広島の自動車産業の発展と共に自動車用シール部品を供給する会社として成長して参りました。

Together with Hiroshima Nishikawa Rubber Co., Ltd.

History of Nishikawa Rubber has started with making sponge rubber sandals and continued to focus on sponge technology. Although Nishikawa Rubber has lost its plant and many lives of employees due to the Second World War, Mr. Nishikawa and few surviving employees have decided to continue on the path they set out previously on regardless of obstacles they had to overcome and has become an automotive sealing supplier and has grown as automotive industry in Hiroshima develops.

Together with Hiroshima Nishikawa Rubber Co., Ltd.

History of Nishikawa Rubber has started with making sponge rubber sandals and continued to focus on sponge technology. Although Nishikawa Rubber has lost its plant and many lives of employees due to the Second World War, Mr. Nishikawa and few surviving employees have decided to continue on the path they set out previously on regardless of obstacles they had to overcome and has become an automotive sealing supplier and has grown as automotive industry in Hiroshima develops.

全てはスポンジ草履から始まった。

It all started with sponge rubber sandals.

It all started with sponge rubber sandals.

当時の仕上げライン。

Finishing line at that time.

Finishing line at that time.

ドアウェザーストリップ

Door weatherstrips

Door weatherstrips

「正社員の証として名前入りの番傘が配布された。

嬉しくて母と喜んだのを思い出す」

当時の従業員

"Personalized umbrella was given as a proof of fulltime employment. I still remember how delighted I was with my mother when I received it."

Former Employee

嬉しくて母と喜んだのを思い出す」

当時の従業員

"Personalized umbrella was given as a proof of fulltime employment. I still remember how delighted I was with my mother when I received it."

Former Employee

現在

戦後のモータリゼーションの流れの中で、自動車用部品の製造を始めたことが現在の西川ゴム工業の事業形態の基礎となっています。

生き残った少数の従業員たちと再建した広島の町工場は、今ではウェザーストリップ国内シェアNo.1(注1)を誇るまで成長しました。現在では米国・中国・タイ・インド・メキシコ・インドネシア等の国々へ進出し、グローバルな事業展開を行っています。西川ゴムは世界各国の地域発展に貢献していきます。

(注1)当社集計

Nishikawa Rubber started manufacturing automotive parts when the tide of the post war motorization arrived. It has now become a fundamental of our business. A small factory in Hiroshima that was rebuilt by few remaining employees has now grown to a company takes great pride in being top weatherstrip market share in Japan. At present, Nishikawa Rubber is a Global company with locations in the U.S.A., China, Thailand, India, Mexico and Indonesia. Nishikawa Rubber has committed to promoting regional development around the globe.

(注1)当社集計

Nishikawa Rubber started manufacturing automotive parts when the tide of the post war motorization arrived. It has now become a fundamental of our business. A small factory in Hiroshima that was rebuilt by few remaining employees has now grown to a company takes great pride in being top weatherstrip market share in Japan. At present, Nishikawa Rubber is a Global company with locations in the U.S.A., China, Thailand, India, Mexico and Indonesia. Nishikawa Rubber has committed to promoting regional development around the globe.

Diversity and Inclusion

誰もが幸せに働ける職場

Workplace where everyone can work happily

誰もが幸せに働ける職場

Workplace where everyone can work happily

The best possible solution for the sealing systems

高度なシーリングシステム

Complex Sealing Systems

高度なシーリングシステム

Complex Sealing Systems

Natural products

人にやさしい100% こんにゃくスポンジ

Shower sponge made 100% from konjac potatoes

人にやさしい100% こんにゃくスポンジ

Shower sponge made 100% from konjac potatoes

Investment in the future

未来への投資。大学への寄付。

Donation to a University

未来への投資。大学への寄付。

Donation to a University

飛躍的に拡大・進化するモビリティ‐ライフ

西川ゴムは、サスティナブルな快適空間を独自の「シール&フォーム技術」で築きます

Rapidly Expanding and Progressing mobility as a Lifestyle

Nishikawa Rubber creates sustainable and comfortable space with its own "Seal & Foam Technology"

Rapidly Expanding and Progressing mobility as a Lifestyle

Nishikawa Rubber creates sustainable and comfortable space with its own "Seal & Foam Technology"

バイオマス材料の活用拡大

Biomass material

自動車用ドアシール材 ウェザーストリップは、ドアまわりに装着して車室内への雨・風・騒音の侵入を防ぐ、快適ドライブになくてはならないアイテムです。これは、主に合成ゴムや樹脂などからつくられますが、西川ゴムでは、バイオマス原料や再生材料を使用した「地球環境に配慮したウェザーストリップ」の研究開発を進めています。

Door weatherstrips seal the edges of doors when they are closed, preventing the rain, the wind and the noise.They maintain the comfort in the car cabin. Weatherstrips are currently made of synthetic rubber or plastic, but Nishikawa Rubber is studying eco-friendly weatherstrips made from biomass materials and recycled materials.

Biomass material

自動車用ドアシール材 ウェザーストリップは、ドアまわりに装着して車室内への雨・風・騒音の侵入を防ぐ、快適ドライブになくてはならないアイテムです。これは、主に合成ゴムや樹脂などからつくられますが、西川ゴムでは、バイオマス原料や再生材料を使用した「地球環境に配慮したウェザーストリップ」の研究開発を進めています。

Door weatherstrips seal the edges of doors when they are closed, preventing the rain, the wind and the noise.They maintain the comfort in the car cabin. Weatherstrips are currently made of synthetic rubber or plastic, but Nishikawa Rubber is studying eco-friendly weatherstrips made from biomass materials and recycled materials.

高難度リサイクルに挑戦

Challenging difficult recycling

製造過程でやむなく発生するスクラップ(廃材)。ゴムの場合、これを再び同じ製品にリサイクルすることはとても難しく、これまでは燃料資源として活用するのが一般的でした。西川ゴムでは、ここに新たな英知のリサイクル技術を投入し、量産適用への研究を進めています。

Scraps are typically viewed as necessary evils when manufacturing. It has been very difficult to recycle rubber materials, so scrap rubbers are normally used as fuels. Nishikawa Rubber is now trying to introduce recycled rubber in to production by using the latest technology.

Challenging difficult recycling

製造過程でやむなく発生するスクラップ(廃材)。ゴムの場合、これを再び同じ製品にリサイクルすることはとても難しく、これまでは燃料資源として活用するのが一般的でした。西川ゴムでは、ここに新たな英知のリサイクル技術を投入し、量産適用への研究を進めています。

Scraps are typically viewed as necessary evils when manufacturing. It has been very difficult to recycle rubber materials, so scrap rubbers are normally used as fuels. Nishikawa Rubber is now trying to introduce recycled rubber in to production by using the latest technology.

西川ゴム工業(株)

当社は,コア技術である発泡・密封技術を駆使し,主力である自動車用ウェザーストリップを通じて世界中のお客様へここち良さをお届けしております。

広島県広島市西区三篠町二丁目2番8号

復興に尽力した企業に残る80年前からの資料を基に、広島在住のクリエイターの視点を介し復興を感じ取る場「Pride of Hiroshima」の展示を現地でご覧ください。

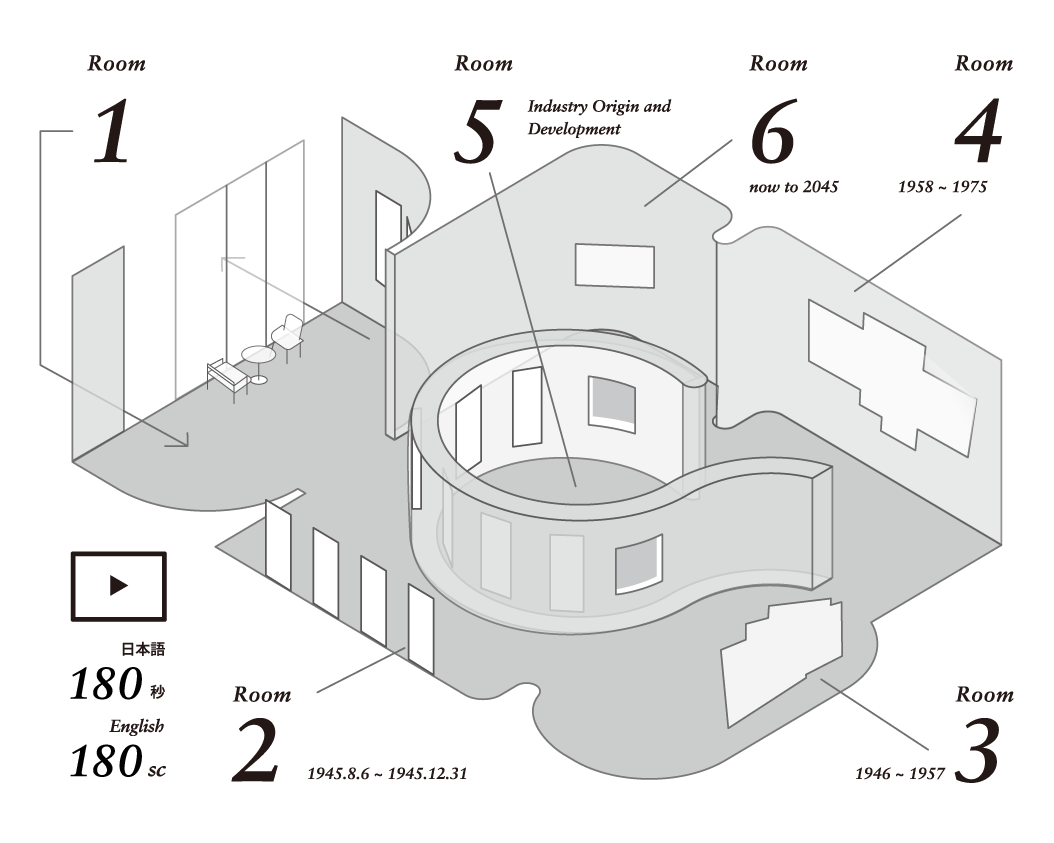

Divide the footprints of the era related to reconstruction into six categories

Please take a look at the "Pride of Hiroshima" exhibition, a place where you can get a sense of the recovery through the perspective of creators living in Hiroshima, based on documents from 80 years ago that remain at companies that worked hard for the recovery.

お問い合わせ